Employing such a standardized document offers several advantages. It streamlines the reordering process, ensures the correct parts are sourced, reduces inventory holding costs by optimizing stock levels, and promotes proactive maintenance strategies. Furthermore, it aids in budgeting for future repairs and facilitates knowledge transfer among maintenance personnel.

parts

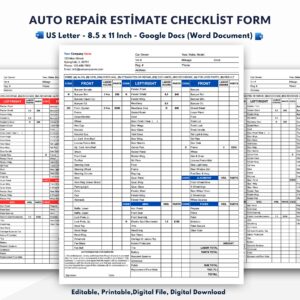

Car Repair Parts List Template

Employing such a standardized format streamlines the repair process, reducing delays caused by missing items. It contributes to accurate cost estimation, helping to manage budgets effectively. Furthermore, it provides a clear audit trail of materials used, useful for record-keeping and warranty purposes.

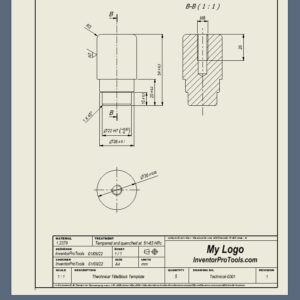

Autodesk Inventor Parts List Template

Employing this structured format delivers several advantages. It minimizes errors in material procurement and assembly by providing a clear and consistent source of information. The automation of data extraction saves significant time and effort compared to manual creation. Moreover, a well-structured listing contributes to improved communication between design, manufacturing, and purchasing departments, leading to streamlined project execution and reduced costs.

Auto Parts Price List Template

Adopting this organized format offers numerous advantages, including streamlined price adjustments, reduced errors in quotations, and improved clarity for both internal personnel and external customers. It also enhances brand consistency across all customer-facing documentation.

Critical Spare Parts List Template

Employing such a resource offers several advantages. It streamlines maintenance processes by offering a ready reference for ordering parts. It minimizes the risk of prolonged equipment outages by ensuring readily available components. Furthermore, it contributes to optimized budget allocation through proactive inventory management.