Employing such a resource minimizes errors, reduces delays, and prevents cost overruns. By confirming all required items are present before starting the project, potential trips to the supply store during work hours are avoided. This proactively contributes to efficient project management, prevents incorrect material substitutions, and helps maintain budget control. Furthermore, it aids in standardization across projects, facilitating consistent quality and simplifying material ordering processes.

material

Material List Template And Plan List

Employing a pre-designed framework for these records offers significant advantages. Such frameworks facilitate standardization, improve accuracy, reduce errors, and enhance communication among project stakeholders. They also streamline the planning process, enabling quicker project initiation and improved overall project management efficiency. These benefits contribute to better resource control, optimized workflows, and ultimately, more predictable project outcomes.

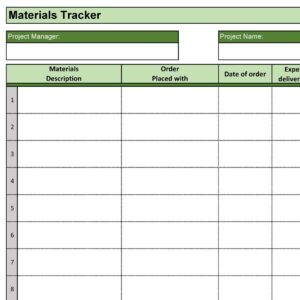

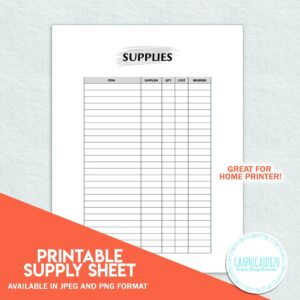

Material Check Off List Template

Utilizing such a document promotes efficiency and accuracy. It reduces the likelihood of project interruptions due to unforeseen material shortages. This, in turn, enhances productivity and can contribute to cost savings by minimizing downtime and rework. Consistent use also aids in standardization of processes, leading to improved quality control and accountability across various operations.

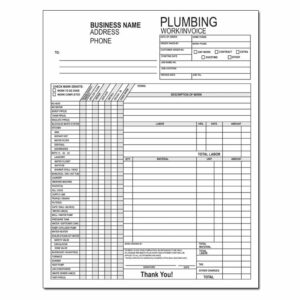

Printable Construction Material List Template

The advantages of employing such a standardized format are numerous. It minimizes errors in ordering, prevents overspending on materials, and streamlines the purchasing process. Furthermore, it enhances communication among project stakeholders, including contractors, suppliers, and clients, by providing a clear and consistent point of reference. This improved clarity contributes to efficient project execution and reduces the likelihood of costly delays.

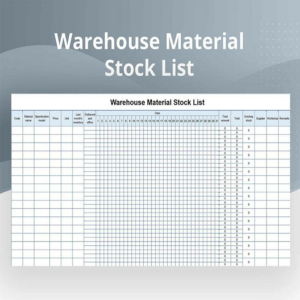

Material Take Off List Template

Employing such a standardized format offers numerous advantages. Precise cost projection becomes feasible, facilitating informed budgeting and financial management. Optimized procurement strategies can be developed, reducing unnecessary expenses and ensuring timely material availability. Furthermore, the risk of errors during ordering and installation phases is significantly diminished, contributing to improved project efficiency and reduced overall project timelines. The standardized structure streamlines communication between project stakeholders, including designers, contractors, and suppliers.