3D Printing

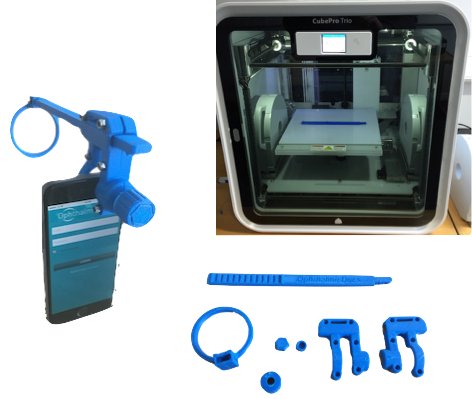

One of our collaborators from the Department of Neurosurgery at the Leeds General Infirmary recently asked us if we could help with some 3D printing. They wanted to fabrictae the oDocs Fundus - an open-source smartphone based retinal camera. Fundus photography involves capturing a photograph of the back of the eye and the devices used in hospitals to do this can cost thousands of pounds. This innovative kit allows you to adapt a smartphone and provide a very cheap solution.

We were happy to help with this request, particularly as it was such a good excuse to use the 3D printing facility that we have in the faculty at Thornton Science Park. The CAD models needed can be downloaded from the oDocs web site. Below you can see one of our CubePro Trio 3D printers producing the first of the seven component parts needed.

It took around 3 hours of printing to fabricate the components (including a few failed attempts). A bit of fine tuning was needed to set up the printer correctly, and we still needed to file away some of the plastic to get a good build. The result can be seen in the photo where the assembled adaptor is attached an iPhone. It still needs a lens in the circular holder before it is fully functioning but they have one waiting at Leeds.

A 3D printer is certainly a useful tool to have available and they are becoming more affordable. The CubePro Trio can be purchased for £2000.

Out thanks to Alice Gillett and David Waugh from Mechanical Engineering for their help with using the 3D Printers.